| |

| What is Private Label Manufacturing |

| Private label manufacturers offer quality product manufacturing services under different brand names and along with varied volume capabilities. The global pharmaceutical industry witnesses amazing growth in terms of process and technology. The manufacturing process has been automated with advance manufacturing facilities and strict regulatory norms. |

| |

| Today, various pharmaceutical Companies outsource their products to private label manufacturers to optimize productivity and improve efficiency. This is true that contract private label manufacturers offer value added services to clients at industry leading prices. Let us have a quick look why private label manufacturing is so popular – |

| |

|

The overall time to market for a particular product has been reduced. |

|

Amazing supply chain management to meet increasing demands of customers. |

|

Improved operational efficiency to increase core business values |

|

Business risks management with adoption of best business strategies. |

|

| |

| Here, it is necessary for pharmaceutical Companies to decide on right outsourcing partner for high quality products, flexible operations, best manufacturing standards, strong quality commitment, reputed background and hands-on experience on new technologies. The outsourcing partner should also be able to work on competitive costs by adopting best tools and techniques and satisfied customer base. |

| |

| Sonus international – Your trusted private label manufacturers |

| |

At Sonus International, our plant is equipped with modern infrastructure facilities to satisfy complex demands of our customers. All of our products are GMP certified and we always stay ahead in global competitive market.

We are able to run production in multiple batches and each order is completed in committed time frame only. With advance tools and packaging facilities, our products are widely appreciated in international market. We have all significant tools to process capsules, tablets, blister packaging, liquid filling etc.

To know more about our contract manufacturing facilities and to place your order for the same, contact our manufacturing team right away.

|

|

|

|

| |

| Benefits of Private Label Manufacturing |

| Benefits of outsourcing services are well known by the pharmaceutical industry: |

| |

| Reducing time to market. The time to market of a particular product is one of the key underlying factors behind the profitability of a company. In the pharmaceutical industry, a delay of even a day while getting a product to the market can cost the company millions of dollars. As a result, achieving the quickest possible time to market is a key challenge for companies. “Sonus International” as a Private Label manufacturer strive to address this challenge. |

|

|

|

| |

| Optimizing the supply chain. One of the key challenges to achieving competitiveness in the pharmaceutical industry is the management of the supply chain. The pharmaceutical supply chain can be optimized by utilization of the services of Private Label manufacturer. |

| |

|

Providing a back up position |

|

Reducing risk and debt |

|

Providing expertise |

|

Providing equipment and flexibility (relieves manufacturing constraints) |

|

Providing cost control |

|

Allowing focus on core activities (refocusing organization, re-engineering processes |

|

Accommodating business downsizing needs, focusing on business-critical tasks) |

|

Providing improved operational quality (increased expertise, benefits from the core business expertise of specialized partners) |

|

Allowing improvement of productivity (economies of scope, increased flexibility, improve time-to-market) |

|

Providing control of business risk (increased access to diverse technologies, access to technologies without capital investment, reduced technical obsolescence risk) |

|

| |

| Pharmaceutical companies have to select the best outsourcing partner for satisfying their needs – a poor choice could cause delays and quality problems and even jeopardise regulatory approval. Issues to consider include : |

|

|

Commitment to quality |

|

Meet best practices and standards for GMP & cGMP |

|

Flexibility |

|

Reputation |

|

Client references |

|

Well-trained and experienced staff |

|

Validated systems and processes |

|

Therapeutic experience |

|

Staff background |

|

Experience with new technologies |

|

Costs including capital and tooling costs |

|

Price |

|

Location ease of interaction |

|

Financial stability |

|

Technology transfer capability |

|

Responsiveness to customer demands |

|

Cultural fit |

|

| |

| A number of pre-conditions, features and capabilities are inevitable to successfully running a business. The key deciding factors are outlined below: |

|

|

Mutual trust and respect. |

|

High priority for a project. |

|

Clear, concise and well established rules. |

|

Open and efficient communication (required for the success of any contract relationship → face to face meetings during the whole activity, conference calls, e-mail, etc.). |

|

Rational cost. |

|

Regulatory documentation (protocols, format, type and date of presentation) defined and approved by client prior to starting the project. |

|

Flexible contract template for an easy agreement that is not time-consuming (it can take months to sign a contract because negotiations for terms and conditions usually stretch out the longest). |

|

| |

| Nonetheless, in the outsourcing business, on time service is the key to growth. Few private label manufacturers offer on time services to their clients, “Sonus International” is one of them.

Sonus International offers private label consulting & service providing specializing in the Private Label Manufacturing of the pharmaceutical products and prescribers prefer. |

|

|

| |

|

|

Raw material supply, Custom designing services, production, best formulations, high-end packaging, labelling, regular updates and high standard documentation.

Multiple sized batch production, proper blending, mixing, product development and formulation, capsule filling, tablet manufacturing, film or sugar coating, proper testing, international documentation, blister packaging etc.

|

| |

| We provide full services from raw materials to finished products: |

|

|

Supply of Raw Materials |

|

Custom Branding Design |

|

Product Formulation |

|

Production |

|

Packaging |

|

Bottling and Labeling |

|

Regulatory Submission |

|

International Documentation |

|

|

|

|

| |

| CONTRACT MANUFACTURING & PRIVATE LABEL MANUFACTURING |

|

|

| Services that we offer to our clients include: |

|

|

Small to Large Batch Production |

|

Powdering, Blending & Mixing |

|

Formulation & Product Development |

|

Hard 2-piece Capsule Filling |

|

Tableting |

|

Softgels (Liquid and Oil) |

|

Liquid Extraction and Filling |

|

High Efficiency Intelligent Film Coating |

|

Solid Dosage Bottling and Labeling |

|

Blister Packaging |

|

Analytical Testing |

|

Microbiology Lab |

|

Export Documentation |

|

| |

| Facility |

| Sonus International has a fully equipped facility that is ready to satisfy each of our customers’ needs: |

|

|

Equipped with sophisticated tools and technologies. |

|

Well-equipped infrastructure to complete variable demands of customers. |

|

GMP certifications and strict quality management system. |

|

Ability to run multiple sized batch production |

|

| |

| Equipment |

| Our advanced and state-of-the-art pharmaceutical manufacturing and packaging equipment is capable of carrying fast and top quality productions.

Our equipments are high speed to ensure a maximum production, automatic for a minimized production time, and efficient to satisfy customers’ needs.

Our equipments are capable of producing: |

|

|

Capsules |

|

Softgels |

|

Tablets |

|

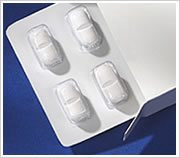

Blister packaging |

|

Liquid filling |

|

|

| |